Kolkata Chemical: Your Premier Caprolactam Partner in India

Step into the world of Kolkata Chemical, a pioneering force in Caprolactam manufacturing, supply, and distribution in India. With an unwavering dedication to quality, we proudly offer an extensive range of Caprolactam products meticulously crafted to cater to the diverse needs of industries within India and around the world.

Product Details:

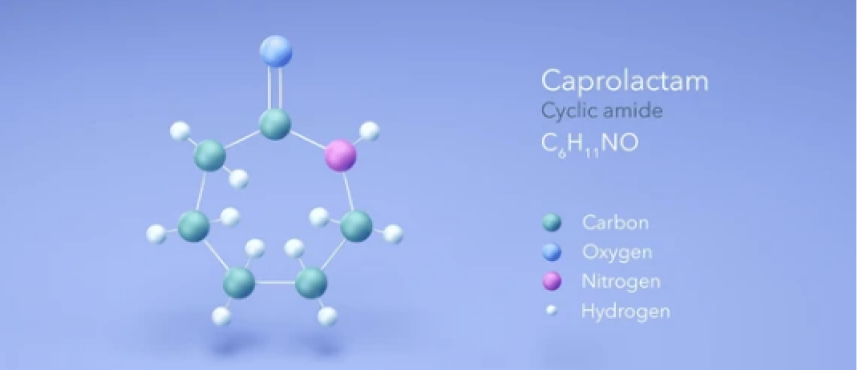

- CAS Number: 105-60-2

- Chemical Formula: C6H11NO

- Product Description: Caprolactam, a cornerstone in Nylon 6 production, is created through the cyclization of aminocaproic acid.

- Usage and Application: Caprolactam is a versatile chemical compound that serves as the raw material for the production of nylon 6, a widely used synthetic polymer. Nylon 6, also known as polyamide 6, is a durable and versatile material with a range of applications across various sectors. Caprolactam is derived from cyclohexanone, which can be obtained from petroleum or natural gas sources. In this comprehensive report, we will explore the applications and uses of caprolactam and its derivative nylon 6 in different sectors, covering their properties, processing methods, and advantages in each application.

1. Textile and Apparel Industry: Nylon 6, produced from caprolactam, is a cornerstone of the textile and apparel industry due to its exceptional properties.

- Clothing: Nylon 6 fibers are used in the production of clothing items such as sportswear, activewear, lingerie, and outerwear for their strength, flexibility, and moisture-wicking properties.

- Hosiery: Nylon 6 is used to create hosiery and stockings for its elasticity and durability, providing comfort and aesthetic appeal.

- Sporting Gear: Nylon 6 fabrics are used in sportswear, including jerseys, shorts, and swimwear, due to their durability and ability to withstand intense physical activity.

2. Automotive Industry: Nylon 6 is employed in the automotive sector for its mechanical properties, heat resistance, and weight reduction potential.

- Interior Components: Nylon 6 is used to create interior components such as upholstery, carpeting, and door panels due to its durability and resistance to wear.

- Under-the-Hood Parts: Nylon 6 is used for producing under-the-hood parts like engine covers, radiator tanks, and oil filters for its heat resistance and strength.

3. Engineering Plastics and Industrial Applications: Nylon 6 is extensively utilized in engineering plastics due to its mechanical strength, toughness, and resistance to chemicals.

- Manufacturing Components: Nylon 6 is employed to produce components like gears, bearings, and bushings due to its wear resistance and low friction properties.

- Machinery Parts: Nylon 6 is used in various machinery parts requiring high mechanical strength and resistance to chemicals.

4. Electrical and Electronics Industry: Nylon 6 finds applications in the electrical and electronics sector due to its insulating properties and resistance to heat.

- Cable Insulation: Nylon 6 is used as cable insulation due to its electrical insulating capabilities and ability to withstand elevated temperatures.

- Connector Components: Nylon 6 is used for creating connector housings, terminals, and enclosures for electronic devices due to its mechanical properties and flame resistance.

5. Consumer Goods: Nylon 6 is a fundamental material in various consumer goods due to its durability and aesthetic appeal.

- Kitchen Utensils: Nylon 6 is used in the production of kitchen utensils like spatulas, ladles, and cutting boards for its resistance to heat and toughness.

- Tool Handles: Nylon 6 is employed to make handles for tools and equipment due to its mechanical strength and comfortable grip.

6. Filament Yarns and Textiles: Nylon 6 is used to create filament yarns and textiles for its strength, flexibility, and versatility.

- Thread and Sewing: Nylon 6 is used to create strong and durable sewing thread due to its high tensile strength and abrasion resistance.

- Industrial Fabrics: Nylon 6 fabrics are used in industrial applications like conveyor belts, safety nets, and tents due to their strength and durability.

7. Packaging Industry: Nylon 6 finds applications in the packaging sector due to its strength, flexibility, and barrier properties.

- Food Packaging: Nylon 6 is used as a barrier material in food packaging to preserve freshness and extend shelf life for perishable items.

- Industrial Packaging: Nylon 6 is employed in industrial packaging materials such as films, pouches, and bags due to its durability and strength.

8. Medical and Healthcare: Nylon 6 is utilized in medical and healthcare applications due to its biocompatibility and strength.

- Surgical Sutures: Nylon 6 is used to manufacture surgical sutures due to its biocompatibility, tensile strength, and ability to be absorbed by the body.

- Orthopedic Implants: Nylon 6 is employed in orthopedic implants, such as bone screws and rods, due to its mechanical properties and biocompatibility.

9. Furniture and Home Furnishings: Nylon 6 is used in furniture and home furnishings due to its durability and versatility.

- Chair Components: Nylon 6 is used to create components for chairs, such as armrests, casters, and frames, due to its mechanical strength and stability.

- Upholstery: Nylon 6 fabrics are used in upholstery for furniture like couches and chairs due to their resistance to wear and staining.

10. Industrial Applications: Nylon 6 serves various industrial applications due to its strength, chemical resistance, and versatility.

- Ropes and Cords: Nylon 6 is used in the production of ropes, cords, and industrial cables due to its high tensile strength and resistance to abrasion.

- Seals and Gaskets: Nylon 6 is employed to create seals, gaskets, and O-rings due to its resistance to chemicals and durability.

11. Aerospace Industry: Nylon 6 finds applications in the aerospace sector due to its lightweight nature and ability to meet stringent safety standards.

- Aircraft Components: Nylon 6 is used in various aircraft components such as interior panels, brackets, and connectors due to its mechanical properties and flame resistance.

- Satellite Components: Nylon 6 is used in satellite components due to its low outgassing properties and resistance to radiation.

12. Filtration and Separation: Nylon 6 is used in filtration and separation applications due to its durability and filtration properties.

- Industrial Filtration: Nylon 6 is used in industrial filtration systems for its ability to capture particles, contaminants, and liquids.

- Liquid Filtration: Nylon 6 membranes are employed in liquid filtration applications due to their resistance to chemicals and high flow rates.

13. Marine and Nautical Applications: Nylon 6 is used in marine applications for its resistance to moisture, strength, and durability.

- Boat Accessories: Nylon 6 is employed to create boat accessories such as cleats, fenders, and ropes due to its resistance to saltwater and harsh marine conditions.

- Sails and Rigging: Nylon 6 is used in sailing equipment like sails and rigging for its lightweight nature and durability.

14. Renewable Energy: Nylon 6 is finding applications in the renewable energy sector due to its durability and resistance to outdoor conditions.

- Wind Turbine Components: Nylon 6 is used in wind turbine components such as blades and structural elements due to its mechanical strength and resistance to UV radiation.

, caprolactam and its derivative nylon 6 have a wide range of applications across various sectors. The versatility of nylon 6, driven by its exceptional properties, including strength, heat resistance, durability, and versatility, makes it invaluable in textiles, automotive, engineering plastics, electronics, packaging, consumer goods, medical, filament yarns, furniture, industrial applications, aerospace, filtration, marine, renewable energy

Product Parameters:

- Grade Standard: Industrial Grade

- Certification: ISO 9001:2015

- Purity: Exceeding 99.5%

- Appearance: Crystalline solid

- Specifications: Customizable to meet specific industry requirements

Our Advantages:

- Vast industry experience and expertise

- Cutting-edge manufacturing infrastructure

- Stringent quality control protocols

- Customization options for tailored solutions

- Significant production capacity ensuring consistent supply

Production Capacity: Our state-of-the-art production facility boasts a substantial annual capacity, ensuring a seamless and dependable supply of Caprolactam products to meet market demands.

Quality Control: Quality is not just a commitment but an ethos at Kolkata Chemical. Our rigorous quality control procedures encompass exhaustive testing and inspections, ensuring that our products consistently exceed industry standards.

Customization: Recognizing the unique needs of each client, we offer customized Caprolactam formulations tailored to precise requirements.

Company Info: Kolkata Chemical proudly stands as an epitome of innovation and quality in the realm of specialty chemical manufacturing and distribution. Our unwavering dedication to excellence has garnered the trust not only within India but also across the Middle East and globally.

Packing: Our Caprolactam products are thoughtfully packaged in various formats, ensuring secure transportation and storage while preserving the integrity of the product.

Physical Properties:

- Melting Point: 68-69°C

- Density: 1.02 g/cm³

- Solubility in Water: Fully miscible

Storage: For optimal preservation of its properties, store Caprolactam in a cool, dry place, away from direct sunlight and moisture.

Quality Inspection: Each batch of our Caprolactam undergoes meticulous quality inspections, assuring uniformity and adherence to specifications.

Plant Area: Our expansive manufacturing facility spans a significant area, equipped with cutting-edge technology to fulfill market requirements.

Terms of Payment or Quotation & Payment: We offer flexible payment terms and competitive quotations, ensuring convenient access to our premium Caprolactam products.

Nearest Port: Strategically located, our facilities provide swift access to ports, facilitating efficient shipping and distribution.

Import & Export Mode: Operating on both import and export modes, we ensure seamless cross-border transactions, enhancing accessibility to our global clientele.

Cities We Serve: Kolkata Chemical proudly caters to major cities within India and also extends its reach to industrial hubs in the Middle East, including Dubai, Abu Dhabi, Riyadh, Doha, Shanghai, New York, and Frankfurt.

Kolkata Chemical emerges as the definitive choice for Caprolactam supply, manufacturing, and distribution. Our unwavering dedication to quality, innovation, and customer satisfaction has positioned us as the partner of choice for industries seeking excellence in crucial chemical raw materials. Partner with us to experience unparalleled quality across every facet of our product range.

For inquiries and orders, please get in touch with us at Email-

chemicalkolkata@gmail.com