Kolkata Chemical: Steering the Butadiene Revolution from India’s Cultural Capital

From the heart of India’s cultural nexus, Kolkata, emerges a giant that’s redefining the paradigms of chemical supply – the Kolkata Chemical enterprise. Navigating the dynamic lanes of Butadiene supply, manufacturing, and distribution, this behemoth, rooted in rich traditions, merges quintessential Bengali intelligence with cutting-edge science.

CAS Number: 106-99-0

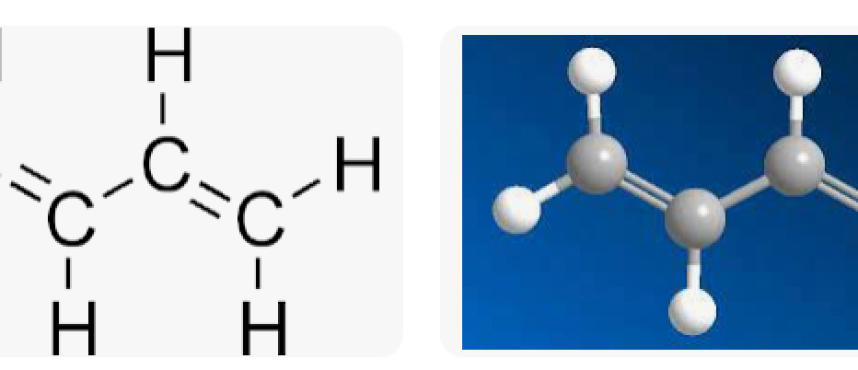

Molecular Formula: C4H6

Product Description

Butadiene is an unsaturated hydrocarbon and is a pivotal constituent in the production of synthetic rubbers and plastic resins. Exhibiting a colorless and gaseous appearance, Butadiene’s indispensability is renowned across several industries.

Usage & Applications

Butadiene, a versatile chemical compound with the molecular formula C4H6, is a crucial building block in the petrochemical industry. It is a key monomer in the production of synthetic rubber and various plastics, playing a significant role in multiple sectors. This comprehensive report explores the applications and uses of butadiene across different industries, covering its properties, processing methods, and advantages in each application.

1. Rubber Industry: One of the primary applications of butadiene is in the rubber industry, where it is used to produce synthetic rubber.

- Styrene-Butadiene Rubber (SBR): SBR is the most common synthetic rubber produced using butadiene. It is used in a wide range of applications, including automobile tires, footwear, and industrial products.

- Polybutadiene Rubber (BR): Polybutadiene rubber, produced from butadiene, is known for its high resilience, low hysteresis, and excellent abrasion resistance, making it suitable for tire treads and other high-wear applications.

2. Plastics and Polymers: Butadiene is a vital monomer for the production of various plastics and polymers.

- Styrene-Butadiene (SB) Copolymers: Butadiene is copolymerized with styrene to produce high-impact plastics used in products such as packaging materials, toys, and consumer goods.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a thermoplastic terpolymer composed of acrylonitrile, butadiene, and styrene. It is used in applications like automotive parts, electronic housings, and consumer products.

- Nitrile Rubber (NBR): NBR is produced by copolymerizing butadiene with acrylonitrile. It has excellent oil and fuel resistance, making it suitable for automotive parts, hoses, seals, and gloves.

3. Automotive Industry: Butadiene-derived products find extensive use in the automotive sector.

- Tire Manufacturing: The majority of synthetic rubber produced from butadiene is used for tire manufacturing, contributing to the safety, durability, and performance of vehicles.

- Automotive Parts: Polymers and plastics derived from butadiene are used for various automotive components, including bumpers, interior trim, and seals.

4. Footwear Industry: Synthetic rubber produced from butadiene is a key component in the footwear industry.

- Sneaker Soles: Butadiene-based rubber compounds are used for the soles of sneakers and other footwear, providing cushioning, grip, and durability.

- Industrial Footwear: Butadiene-based materials are also used for industrial and safety footwear due to their resistance to oils, chemicals, and abrasion.

5. Adhesives and Sealants: Butadiene-derived polymers are used in adhesives and sealants for various applications.

- Construction Adhesives: Butadiene-based adhesives are used in construction for bonding flooring materials, tiles, and other surfaces.

- Automotive Sealants: Butadiene-based sealants are used in the automotive industry for sealing joints and gaps, preventing water and air infiltration.

6. Textile Industry: Butadiene derivatives have applications in the textile industry.

- Elastane Fibers (Spandex): Butadiene is used in the production of elastane fibers, also known as spandex or Lycra, which provide stretch and flexibility to clothing, sportswear, and hosiery.

- Performance Fabrics: Butadiene-based materials are used in the production of performance fabrics with properties such as moisture-wicking, breathability, and comfort.

7. Coatings and Paints: Butadiene-based polymers are used in coatings and paints.

- Architectural Coatings: Butadiene-based coatings are used in architectural paints for exterior and interior surfaces due to their durability and adhesion properties.

- Industrial Coatings: Butadiene-derived polymers find applications in industrial coatings for machinery, equipment, and metal surfaces.

8. Consumer Goods: Butadiene-derived materials are used in various consumer goods.

- Household Items: Butadiene-based plastics and polymers are used in the production of everyday items such as kitchenware, toys, and electronic housings.

- Sporting Goods: Butadiene-based materials are used in the production of sporting goods such as balls, handles, and protective gear.

9. Packaging Industry: Butadiene-derived polymers contribute to the packaging industry.

- Flexible Packaging: Butadiene-based materials are used in flexible packaging films, pouches, and bags for food, beverages, and other products.

- Blister Packaging: Butadiene-derived materials are used in blister packaging for pharmaceuticals, electronics, and consumer goods.

10. Medical Products: Certain butadiene-derived materials have applications in the medical field.

- Medical Gloves: Nitrile rubber, derived from butadiene and acrylonitrile, is used in the production of medical gloves due to its resistance to chemicals and pathogens.

- Medical Tubing: Butadiene-based materials are used in medical tubing for fluid transfer applications.

butadiene plays a pivotal role in various sectors, primarily as a key monomer for the production of synthetic rubber and plastics. Its applications span across the rubber industry, automotive sector, footwear industry, adhesives, textiles, coatings, consumer goods, packaging, and even medical products. As industries continue to evolve and sustainability gains importance, the applications of butadiene-derived materials are likely to expand further, contributing to their significance in modern manufacturing and innovation.

Product Parameters

Grade Standard: Elite Industrial and High-Grade Specialty

Certification: ISO 9001, REACH, ISI

Purity: ≥99.5%

Appearance: Transparent Colorless Gas

Specifications

- Boiling Point: -4.7°C

- Density: 0.62 kg/m3 at its boiling point

Our Advantages

- Strategic Location: Situated in Kolkata, ensuring unparalleled logistical advantages.

- Innovation-driven: Spearheaded by a dedicated research unit.

- Customer-centric Approach: Tailored solutions for every unique demand.

Production Capacity

With avant-garde infrastructure, Kolkata Chemical has an astonishing production capacity of over 650,000 metric tons annually.

Quality Control

Endowed with futuristic technology, we ensure our offerings meet global quality standards.

Customization

From specific purity requirements to specialized packaging, our capabilities are vast.

Company Info

Plant Area: A sprawling domain encompassing 4 million square meters in Kolkata’s prime industrial hub.

Import & Export Mode: Streamlined channels for seamless import of raw materials and export of the final product.

Nearest Port: Proximity to the Kolkata Port, ensuring swift sea-based shipments.

Packing & Physical Properties

- Packing: High-pressure containers equipped with the latest safety measures.

- Solubility: Moderate in alcohol and ethers.

STORAGE

Butadiene from Kolkata Chemical is housed in technologically advanced storage solutions, ensuring its qualitative integrity.

Quality Inspection

A robust multi-tiered inspection process, sometimes including third-party audits, ensures product excellence.

Quotation & Payment

Transparent business dealings, complemented by a spectrum of payment options including digital transfers and more.

Global Outreach

Kolkata Chemical’s influence isn’t just confined to India. Our reach extends to the markets of Dubai, London, Sydney, New York, Tokyo, and more, marking our global footprint.

Kolkata Chemical is more than a name; it’s a legacy. Nestled in Kolkata, our roots run deep, mirroring the city’s rich heritage. As we evolve, we remain dedicated to excellence, forging relationships that extend beyond mere transactions. With a global vision and grounded values, Kolkata Chemical is set to chart newer territories in the Butadiene domain.

For inquiries and orders, please get in touch with us at Email-

chemicalkolkata@gmail.com