Kolkata Chemical Polycaprolactone Supplier, Manufacturer, and Distributor in India

In the vibrant city of Kolkata, often referred to as the “Cultural Capital of India,” a chemical revolution is on the rise. Kolkata Chemical, an indigenous entity, stands out as a dominant figure in the realm of Polycaprolactone, catering to a myriad of industries with its premium quality, durability, and performance.

CAS Number: 24980-41-4

Molecular Formula: C6H10O2

Product Description

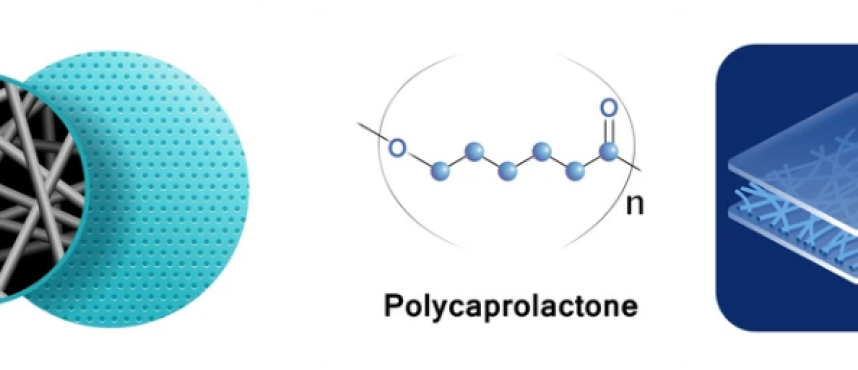

Polycaprolactone (PCL) is a white, semi-crystalline, biodegradable polyester. Its versatility stems from its unique molecular structure and favorable melting point, making it an integral component in several commercial applications.

Usage & Applications

Polycaprolactone (PCL) is a biodegradable and biocompatible thermoplastic polymer that has gained significant attention across various industries due to its unique properties and wide range of applications. PCL’s versatility, ease of processing, and environmental friendliness make it a valuable material in sectors ranging from medical and pharmaceutical to packaging and textiles. In this comprehensive report, we will explore the applications and uses of polycaprolactone in different sectors, covering its properties, processing methods, and advantages in each application.

1. Medical and Healthcare: Polycaprolactone’s biocompatibility and degradation characteristics make it particularly suitable for medical applications.

- Sutures and Surgical Mesh: PCL is used in the production of absorbable surgical sutures and meshes due to its biodegradability and compatibility with human tissue.

- Drug Delivery Systems: PCL-based microspheres and nanoparticles are used as drug carriers for controlled and targeted drug release in pharmaceutical formulations.

- Tissue Engineering: PCL scaffolds are employed in tissue engineering to provide support for cell growth and tissue regeneration, particularly in bone and cartilage repair.

2. Biodegradable Packaging: PCL’s biodegradability and versatility have led to its use in sustainable packaging solutions.

- Food Packaging: PCL-based packaging films and containers are used for food packaging to reduce plastic waste and improve environmental sustainability.

- Single-Use Products: PCL-based packaging for single-use items such as utensils, straws, and cups helps reduce the environmental impact of disposable plastics.

3. 3D Printing: PCL’s low melting point and ease of processing make it a popular choice for 3D printing applications.

- Prototyping: PCL is used for rapid prototyping and modeling in various industries, including automotive, aerospace, and consumer goods.

- Medical Devices: PCL is employed in 3D printing of medical devices and implants, allowing for customized and patient-specific solutions.

4. Textile and Apparel Industry: PCL’s thermoplastic nature and softness make it suitable for textile applications.

- Fibers and Fabrics: PCL fibers are used in textiles for clothing, activewear, and technical fabrics due to their comfort and durability.

- Nonwoven Fabrics: PCL-based nonwoven fabrics are used in applications such as wound dressings, wipes, and hygiene products.

5. Cosmetics and Personal Care: PCL’s biocompatibility and low toxicity make it suitable for cosmetic and personal care products.

- Cosmetic Formulations: PCL is used in cosmetic formulations such as creams, lotions, and ointments for its emollient and moisturizing properties.

- Temporary Tattoos: PCL films are used in temporary tattoo applications due to their flexibility and ability to adhere to skin.

6. Agricultural Applications: PCL’s biodegradability and controlled degradation rate make it useful in agriculture.

- Mulch Films: PCL-based mulch films are used in agriculture to provide weed control, moisture retention, and soil protection, with the added benefit of biodegradation.

7. Renewable Energy: PCL’s biodegradability and versatility have potential applications in the renewable energy sector.

- Biodegradable Composites: PCL-based composites can be used in the production of renewable energy equipment and components with reduced environmental impact.

8. Polymer Blends and Composites: PCL’s compatibility with other polymers allows for the creation of novel materials with enhanced properties.

- Biodegradable Blends: PCL can be blended with other biodegradable polymers to create materials with improved mechanical and degradation properties.

- Nanostructured Composites: PCL-based composites can be reinforced with nanoparticles to achieve specific functional properties, such as enhanced mechanical strength.

9. Electronics and Packaging: PCL’s properties make it suitable for certain electronic and packaging applications.

- Electronic Encapsulation: PCL can be used as an encapsulant in electronic devices to protect components from moisture and environmental factors.

- Protective Packaging: PCL foam is used in protective packaging for delicate and sensitive electronic components during shipping and handling.

10. Education and Research: PCL’s versatility and ease of processing make it a valuable material for educational and research purposes.

- Educational Demonstrations: PCL’s low melting point allows for hands-on demonstrations in educational settings to showcase thermoplastic behavior.

- Material Research: PCL is often used in material science research to explore its properties, processing methods, and potential applications.

polycaprolactone (PCL) is a versatile and environmentally friendly material with a wide range of applications across various sectors. Its biodegradability, biocompatibility, and ease of processing contribute to its significance in medical and healthcare applications, biodegradable packaging, 3D printing, textiles, cosmetics, agriculture, renewable energy, polymer blends, electronics, and more. As industries continue to prioritize sustainability and innovation, PCL’s applications are likely to expand, further solidifying its role in shaping the future of materials and technologies.

Product Parameters

Grade Standard: Commercial Grade, Pharmaceutical Grade, Specialty Grade

Certification: ISO 9001, GMP Certified

Purity: 99.8%

Appearance: Off-white to white, granular or powdered form

Specifications

- Molecular Weight: 14,000 g/mol approx.

- Melting Point: 58-64°C

- Biodegradation: 6-12 months (varies with conditions)

Our Advantages

- Veteran Expertise: Years of experience in the chemical industry.

- Unparalleled Quality: Sourcing raw materials from trusted vendors only.

- Cutting-edge Infrastructure: State-of-the-art production and storage facilities.

- Client-Centric Approach: Tailored solutions to match individual client requirements.

Production Capacity

Our expansive manufacturing unit boasts a capability of producing an impressive 12,000 metric tons of Polycaprolactone annually.

Quality Control

Stringent in-house quality checks, powered by sophisticated instruments, and a dedicated team ensure each batch aligns with global standards.

Customization

Bespoke solutions catering to distinct industrial needs, ensuring client satisfaction.

Company Info

Plant Area: An extensive facility sprawling over 60,000 square meters.

Import & Export Mode: Direct Import & Export, also via trusted trading partners.

Nearest Port: Haldia Port.

Packing & Physical Properties

- Packing: Standardized in 25kg bags, but bulk orders can be customized as per client requirements.

- Solubility: Soluble in most organic solvents, sparingly soluble in water.

STORAGE

Products should be stored in a cool, dry place, shielded from direct sunlight and moisture. Always keep containers sealed.

Quality Inspection

Adhering to international standards, our dedicated team conducts meticulous quality inspections before any shipment.

Quotation & Payment

Transparent and competitive pricing with multiple payment options including T/T, L/C, and others.

Global Reach

Kolkata Chemical is proud to extend its services to top-tier cities across the Middle East and globally: Dubai, Muscat, Riyadh, Jeddah, Abu Dhabi, Cairo, Beirut, Istanbul, London, Paris, New York, Los Angeles, Tokyo, Shanghai, Singapore, and many more.

Kolkata Chemical’s dedication to producing top-tier Polycaprolactone has not only made it a household name in India but also a recognized supplier in many major cities across the world. With unwavering commitment to quality and a drive to innovate, we continue to set benchmarks in the industry.

For inquiries and orders, please get in touch with us at Email-

chemicalkolkata@gmail.com