Kolkata Chemical: Your Premier Styrene-Butadiene Rubber Supplier, Manufacturer, and Distributor in India

Kolkata Chemical cordially invites you to explore the diverse range of our premium Styrene-Butadiene Rubber (SBR) products. As one of the leading suppliers, manufacturers, and distributors of SBR in India, we offer unparalleled quality, reliable solutions, and exceptional customer service. Our goal is to cater to the diverse needs of our clients, ensuring satisfaction across industries and applications. We take pride in driving success to your business by providing high-quality, sustainable rubber solutions.

CAS No.

Styrene-Butadiene Rubber falls under the CAS Number 9003-55-8. This specific identification assures our alignment with global standardization of chemical substances, reflecting our commitment to international compliance and regulation.

Formula

Styrene-Butadiene Rubber (SBR) has a base chemical formula of (C4H6)x·(C8H8)y. This synthetic rubber is known for its balanced properties derived from its two monomers, styrene and butadiene, providing exceptional toughness and durability.

Product Description

Styrene-Butadiene Rubber, manufactured by Kolkata Chemical, is a copolymer of styrene and butadiene. It is a widely used synthetic rubber, known for its excellent abrasion resistance and ageing stability when protected by additives. It has good load-bearing properties and can be used in applications that require resistance to wear and tear. SBR has similar properties to natural rubber, but with greater resistance to abrasion, wear, and water.

Usage

Styrene-Butadiene Rubber (SBR), one of the most widely used synthetic rubbers worldwide, is a copolymer of styrene and butadiene. Known for its excellent abrasion resistance and ability to hold up well in low temperatures, SBR has a vast array of applications in multiple sectors. This detailed guide will delve into the varied uses of Styrene-Butadiene Rubber across different industries.

- AUTOMOTIVE INDUSTRY:

In the automotive industry, SBR is a principal material used in the manufacturing of car tires due to its excellent abrasion resistance and high load-bearing capacity. Additionally, it is utilized in producing gaskets, mats, and other miscellaneous auto parts, contributing significantly to the automobile sector.

- CONSTRUCTION INDUSTRY:

The construction industry benefits greatly from SBR’s unique properties. It is often mixed with concrete or cement to improve their mechanical properties like toughness, flexural strength, and resistance to water and chemicals. SBR latex is also utilized in concrete sealants and waterproofing agents.

- ADHESIVES AND SEALANTS:

SBR’s excellent bonding strength makes it an ideal material for producing adhesives and sealants. These products are used in a range of applications, from bookbinding and carpet installation to packaging and plumbing.

- RUBBER PRODUCTS:

A broad variety of general rubber goods, such as shoe soles, toys, and conveyor belts, are made from SBR due to its high abrasion resistance and good aging stability. It is also used in producing rubberized fabrics and synthetic leather.

- PAPER AND PACKAGING INDUSTRY:

In the paper and packaging industry, SBR is used to make paper coatings that provide gloss, smoothness, and water resistance to the paper. The adhesive properties of SBR also find use in the packaging sector for creating strong and durable packaging materials.

- MEDICAL INDUSTRY:

While less common, SBR has some applications in the medical field as well. It can be used in making latex gloves, and its elasticity and strength make it suitable for certain types of braces and supports.

- INDUSTRIAL APPLICATIONS:

SBR is used to manufacture a variety of industrial goods like hoses, belts, gaskets, and seals due to its excellent resistance to heat and chemicals. It also finds use in mechanical rubber goods and insulation materials.

- AGRICULTURE INDUSTRY:

In the agriculture sector, SBR is utilized in making water irrigation tubes and agricultural membranes. These products help in the efficient distribution of water and aid in creating optimal growing conditions.

- SPORTS INDUSTRY:

SBR is used in the production of athletic tracks and playground surfaces due to its excellent impact resistance and cushioning properties. It also finds use in sports equipment like rubber balls and protective gear.

- MARINE INDUSTRY:

SBR’s resistance to water and moderate resistance to salt solutions make it useful in certain marine applications. It’s often utilized in producing parts like protective covers, seals, and other components exposed to harsh marine environments.

In summary, Styrene-Butadiene Rubber, with its excellent combination of durability, flexibility, and resistance to abrasion and heat, is an essential material in a wide variety of industries. The future of SBR appears promising with continuous research and technological advancements, leading to the development of new applications in various sectors. Whether it’s a car tire, a rubber toy, or a waterproofing sealant, the versatility of SBR cannot be overstated.

Application

Kolkata Chemical’s SBR is widely applied in numerous industries, including automotive, construction, footwear, adhesives, and others. Its excellent properties make it ideal for applications requiring durability, flexibility, and resistance to wear and tear, such as tyres, belts, hoses, gaskets, floorings, mats, and many others.

Product Parameters

Our SBR offers a range of exceptional parameters, such as high tensile strength, superior elongation at break, excellent heat ageing properties, outstanding resistance to abrasion, and good resilience. It exhibits a hardness of around 50-90 Shore A and a tensile strength of 2-20 MPa.

Grade Standard

Kolkata Chemical offers SBR in various grades, including Emulsion SBR (E-SBR) and Solution SBR (S-SBR), each catering to diverse industrial requirements and applications. These different grades ensure that specific needs and performance standards are met accurately.

Certification

We hold prominent certifications including ISO 9001, ISO 14001, and OHSAS 18001, among others, demonstrating our commitment to quality, safety, and environmental sustainability. These certifications endorse our adherence to internationally recognized standards.

Purity

At Kolkata Chemical, we emphasize stringent quality control measures to guarantee the exceptional degree of purity in our SBR, ensuring it meets or exceeds industry standards. Our SBR is consistently produced to have minimal impurities, maintaining optimal performance across applications.

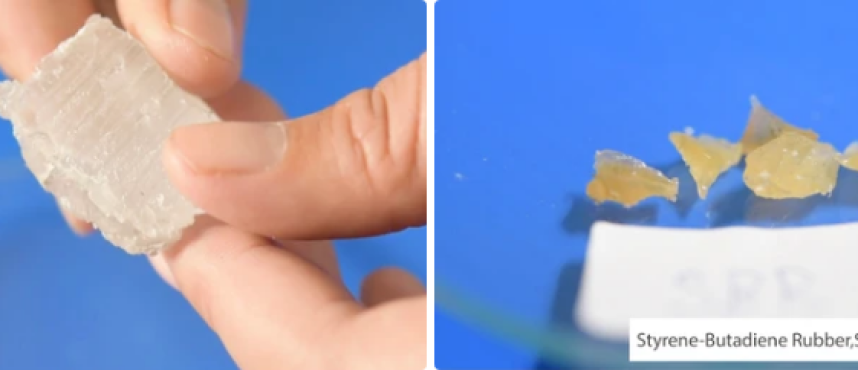

Appearance

Typically, our SBR exhibits a pale yellow to amber color and comes in bale form. The appearance of SBR may undergo slight variations based on specific requirements and enhancements.

Specifications

Our SBR products offer a host of impressive specifications, such as high tensile strength, superior elongation, excellent abrasion resistance, good heat ageing properties, and exceptional resilience. These specifications make our SBR ideally suited for demanding applications.

Our Advantages

Kolkata Chemical stands out in the market through our dedication to delivering value to our customers. We offer a skilled team, cutting-edge production facilities, rigorous quality control, continuous innovation, and a deep understanding of the chemical industry. We follow sustainable business practices and continually invest in research and development, ensuring our ability to meet the evolving demands of our clients.

Production Capacity

Our substantial production capacity enables us to produce several thousand metric tons of SBR annually, ensuring we are equipped to efficiently cater to both large and small orders.

Quality Control

Quality control is paramount at Kolkata Chemical. We meticulously monitor every stage of the production process, from raw material sourcing to final product delivery. Our quality control department conducts thorough testing and inspections to ensure every batch of SBR aligns with our high-quality standards.

Customization

Understanding that each client has unique needs, we offer customization options for our SBR. Whether you require specific formulations, packaging, or delivery schedules, we strive to cater to your specific requirements.

Company Info

Established in Kolkata, the cultural hub of India, Kolkata Chemical is a renowned supplier, manufacturer, and distributor of SBR, with years of industry experience under our belt. Our commitment to quality, innovation, and customer satisfaction has positioned us at the pinnacle of the chemical industry, serving clients not just in India but across the globe.

Packing

Our SBR products are packaged meticulously to ensure safe and efficient transportation. Standard packing includes 25kg paper bags, 20kg plastic woven bags, or as per client’s request. We also offer palletization for added convenience and safety.

Physical Properties

Our SBR exhibits exceptional physical properties, such as high tensile strength, superior elongation at break, excellent heat ageing properties, and outstanding resistance to abrasion and wear.

Storage

For optimal shelf-life, our SBR should be stored in a cool, dry, and well-ventilated area, away from direct sunlight and extreme temperature fluctuations.

Quality Inspection

Our comprehensive quality inspection covers the entire manufacturing process. We ensure all our SBR products comply with international quality standards, delivering consistent, reliable products to our customers.

Plant Area

Our manufacturing plant is a state-of-the-art facility situated in Kolkata. It’s designed to maintain high safety and quality standards while optimizing production efficiency.

Terms of Payment or Quotation & Payment

We provide customer-friendly payment terms and accept various forms of payment, including T/T, L/C, and PayPal. Our quotations are competitive and reflective of the prevailing market conditions.

Nearest Port

Our proximity to the Kolkata Port, one of India’s primary seaports, ensures efficient shipping and distribution of our products across the globe.

Import & Export Mode

We operate under a robust import and export model that allows us to serve both local and global customers effectively. Our network ensures the prompt delivery of our products worldwide.

Service Locations

While our headquarters are in Kolkata, we supply to clients globally, spanning across the Middle East and numerous cities worldwide, such as Dubai, Abu Dhabi, Muscat, Riyadh, Doha, New York, London, Singapore, Shanghai, Sydney, and more.

Conclusion

At Kolkata Chemical, we’re more than just a supplier, manufacturer, and distributor of Styrene-Butadiene Rubber – we’re your trusted partner. Our dedication to delivering exceptional quality, consistent service, and innovative solutions sets us apart. With a wealth of industry experience, a talented team, and a future-forward approach, we are well-positioned to exceed your expectations.

Our commitment to your satisfaction fuels our drive for excellence. Choose Kolkata Chemical as your SBR partner and let’s build a prosperous future together.

For inquiries and orders, please get in touch with us at Email-

chemicalkolkata@gmail.com